You may be the owner of a company that currently make a new product. There is of course a lot to do if this is the case. For example, production must be done, but the product must also be designed. A prototype will then be made which will be tested by the target group to find out whether everything works well and if it looks good. Usually, this is not the case and the design must therefore be improved and adjusted. After that stage, a new prototype is made and tested. This cycle will take a while, but eventually the item will be ready to start production. This can be done with the techniques below.

Table of Contents

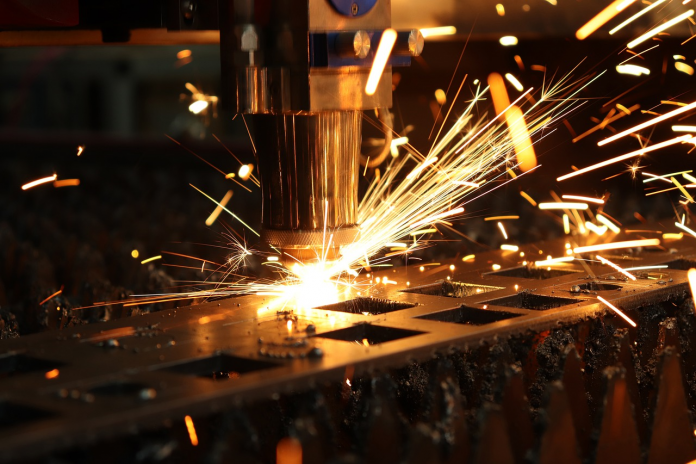

CNC milling

Does the item have to be made of metal instead of plastic? Then it is a lot better to use a subtractive production technology called CNC milling, where CNC stands for Computer Numerical Control. This is a CNC service. The products will be manufactured by removing material from a solid block, which is called either a workpiece or a blank. This is done with the help of multiple cutting tools. A CNC milling machine will also be used to produce the item. By using such a device, you will not have to do much as the machine simply does the production itself.

3D printing

A product can also be created in a different way. For example, you can purchase a 3D printer, although you could also hire 3D print services. By doing this you can 3D print an item. Of course, special machines are used for this. These 3D printers are very fast and are not even very expensive nowadays. You can choose between a lot of different techniques, although a private printer often uses FDM. There are also various materials that you can use for 3D printing, mostly metals and plastics.

Injection molding

You could also decide to use injection molding to make a new product. This is a formative production technology, which means that a product is made by first melting plastic and then injecting it into the cavity of a mold. The material will solidify as it cools, after this it will take the shape of the mold. The product will be ejected from the mold when this process is completed. The process can then start again. So, you can only use injection molding if the product you want to produce should be made of plastic.